How to Use 3D Printing for Product Design and Development

3D printing has revolutionized the field of product design and development, offering unprecedented possibilities and efficiencies. This technology allows designers and engineers to transform digital designs into physical objects quickly and accurately. With 3D printing, intricate and complex prototypes can be easily produced, enabling rapid iterations and cost-effective testing.

It enables the exploration of unique shapes, structures, and functionalities that were once unimaginable. Not only that, but 3D printing facilitates the customization of products, catering to individual needs and preferences.

Here’s a look at how you can take advantage of this technology for your own projects:

Allows for Quick Prototyping

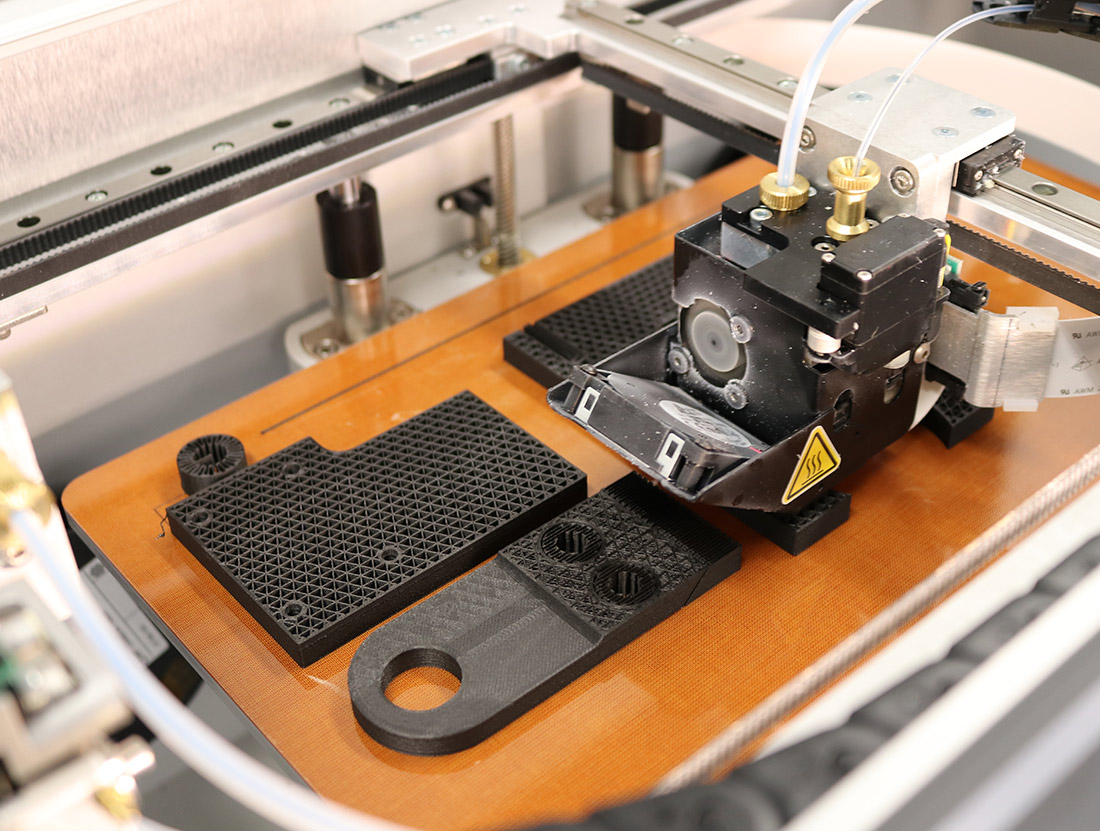

This process allows designers to quickly transform digital designs into physical prototypes, enabling them to visualize and evaluate their ideas in tangible form. With the ability to rapidly iterate designs, identify flaws, and make improvements, 3D printing significantly speeds up the prototyping phase. It helps designers and engineers to test form, fit, and function efficiently, leading to enhanced product development cycles and faster time-to-market. The ease and speed of creating prototypes through 3D printing revolutionize the traditional design process.

Iterative Design and Testing

3D printing allows designers to create and test multiple iterations of their ideas. By producing rapid prototypes, designers can experiment with different designs and customize their prototypes based on user feedback. This leads to better product design, as end-users needs can be effectively considered. Furthermore, 3D printing enables the testing of shapes and structures that are impossible to build using conventional manufacturing methods.

Customization and Personalization

With 3D printing technology, designers can easily modify designs to cater to individual your needs and preferences. This level of customization enables the creation of unique and tailored products, ensuring a better fit for customers. Whether adjusting dimensions, adding personalized features, or incorporating specific details, 3D printing allows for a high degree of personalization, resulting in enhanced customer satisfaction and a competitive edge in the market.

Complex Geometry and Intricate Details

3D printing enables the creation of product designs with complex geometries and intricate details that would be challenging or even impossible to achieve through traditional manufacturing methods. Its layer-by-layer additive manufacturing process allows for precise control over the shape and structure of the object, resulting in highly intricate and visually stunning designs. This capability opens up new possibilities for creating visually appealing and aesthetically unique products, pushing the boundaries of design and offering opportunities for innovation in various industries.

Collaborative Design Process

3D printing is ideal for facilitating collaboration and communication during the design process. Collaborating with colleagues, clients, and designers worldwide over the Internet increases efficiency by reducing communication barriers. It also reduces costs, as multiple teams can work together in real-time. Due to the high degree of customization and personalization achieved through 3D printing, collaboration is essential, enabling designers to better understand end-user needs and desires.

3D printing has revolutionized product design and development, offering numerous advantages in rapid prototyping, customization, intricate detailing, and cost-effective production. It has helped designers and engineers to push the boundaries of innovation, resulting in unique and functional products. Get in touch to discover how Celero Partners can use this technology for your project.