Benefits of 3D Scanning for Product Design

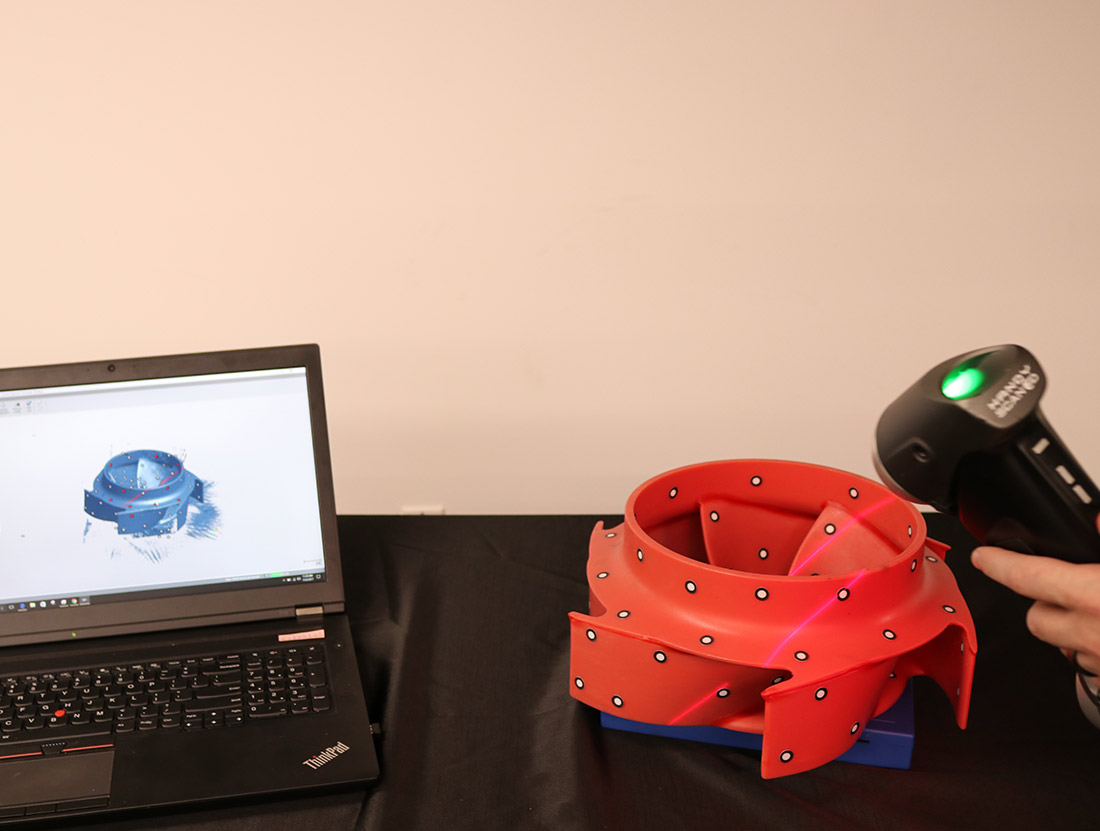

In the growing landscape of prototyping and product design, 3D scanning has transformed the way we bring our ideas to life. Its genius lies in scanning physical objects and converting them into digital models. It may not seem like much, but with an annual growth of 5.7%, this technology has taken over the product designing process.

Read on to find out about a few of the countless benefits of implementing 3D scanning to help design and modify your product.

Precision and Accuracy

One of the main benefits 3D scanning has to offer is the amount of precision and accuracy in its measurements. It’s a major step up from manual tools like measuring tape or calipers. Since they rely on manual handling, these tools will always be prone to measurement errors and limitations.

In contrast, 3D scanners can capture even the microscopic details of a product with zero shortcomings. This level of precision is detrimental in various industries, like engineering, medical, aerospace, etc.

Experiment With Design

With 3D scanning, people can experiment with their designs without reconstructing the actual product. Once it’s scanned, the digital model of the product acts as a canvas, giving designers the opportunity of unrestricted creativity. They can experiment with the shape, size, and different features of the digital product.

This kind of flexibility allows for the exploration and innovation of designs that don’t usually come with traditional methods.

Reverse Engineering Capabilities

3D scanners are the perfect tool for reverse engineering an existing product. After digitizing the product, designers have the free reign to dissect the product and gain insight into its design. This is especially useful in understanding products with intricate mechanisms and complex structures.

Designers can also use this opportunity to improve on existing products. They can easily work to make the product better or fix issues in the original design.

Quality Control

Quality control is vital when it comes to product manufacturing. Without it, there’s a great chance of creating defective products that contradict with the original design. If the quality decreases, it could compromise the product’s functionality.

For this reason, a digital model of the original product would make a perfect blueprint for further manufacturing. Since 3D scanning captures the intricate details of a design, the digitized version would offer every specification needed to make the exact replica.

Handling Complex Designs

As mentioned before, traditional measuring methods can’t record accurate details of a design. When one is dealing with complex geometrical designs, it could lead to a great number of errors and inaccuracies.

3D scanning excels at handling complicated designs and unconventional shapes. It can capture various data points on intricate details, curves, and surfaces. The best part is that 3D scanners can take measurements without physically touching the product, reducing the risk of damaging the detailed surface.

The rise of 3D scanning has reshaped the process of product design. It offers designers opportunities for experimentation and reverse engineering. With the digital models, people can rely on the scan’s accuracy and need for quality control. 3D scanners are the perfect tool for bringing complicated concepts into reality.

Source:

https://www.marketvalueinsights.com/industry-reports/3d-scanning-market/353